Environment

Montana Resources is part of a modern generation of mine operators who strive to innovate processes and utilize more efficient technologies to lessen the impact of mining on the environment.

Water Management

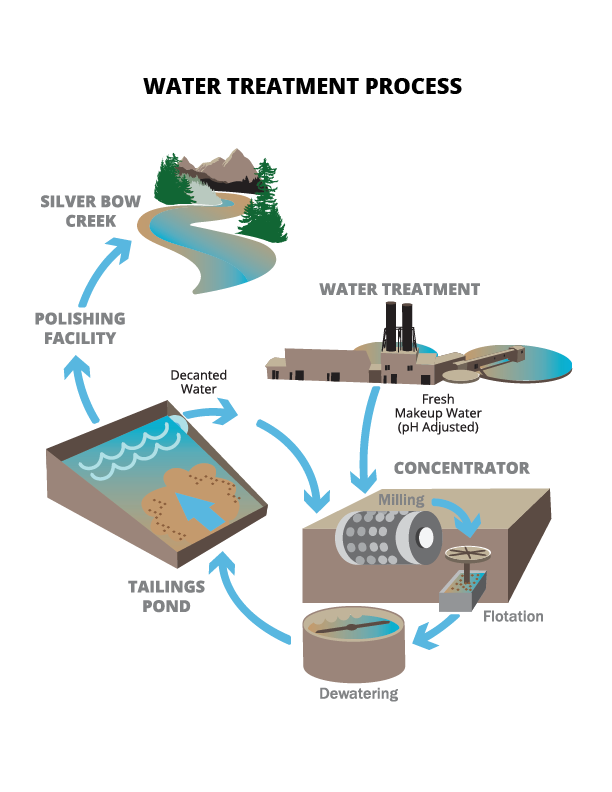

Water is a necessary part of operations. Montana Resources manages stormwater and site water to the maximum extent practicable by recycling these waters and minimizing the importation of off-site water. In fact, the majority of water used for operations is recycled water.

After ore is processed in the concentrator, the remaining material is a pulverized rock slurry that is pumped to the Yankee Doodle Tailings Storage Facility where the flour-sized byproduct of the milling process settles out and the water decants to form a pond. The decanted water is pumped back to the mine operation or to the Polishing Facility for a final treatment step prior to off-site discharge.

Copper is also extracted from water pumped from the nearby Berkeley Pit, as well as other site waters, in precipitation cells. The water remaining after this copper recovery goes through a water treatment plant to remove metals and this is either piped into the mine operations or to the Polishing Facility for final treatment prior to off-site discharge.

Horseshoe Bend Water Treatment Plant is a two-stage high-density sludge lime precipitation process

A fleet of 52,000-gallon capacity water trucks operate to control fugitive dust on haul roads.

Dust collectors, or bag houses, are used in areas of high dust exposure to protect workers and to prevent the release of particulate emissions to the environment.

Air Quality

Montana Resources employs various methods of dust control during drilling and blasting, along the various haul routes, through crushing and conveying, and at the tailings storage facility and holds a current air quality permit through the Montana Department of Environmental Quality.

Any material that does not meet grade for ore is deemed waste rock (or non-ore material). Non-ore material is used for the construction of the tailings storage facility.

Non-Ore Rock

Areas scheduled to be mined are sampled and analyzed for mineral content. If the material meets ore grade, it goes for processing. Material that does not meet ore-grade is considered non-ore rock. Non-ore rock is hauled to the tailings storage area where it is used in the embankment construction or is covered by pH-neutral alluvium, recontoured, and then seeded with a site-specific recipe of native grasses approved by the Montana Department of Environmental Quality including wheatgrass, bluegrass, fescue and wildrye.

Reclaimed slopes can be seen here at the southern end of the Continental Pit, adjacent to the city of Butte.

The result of concurrent reclamation creates grassy rolling hills inhabited by deer, elk, and other wildlife.

Concurrent Reclamation

Unlike most open pit mines that are only reclaimed at the end of mine operations, Montana Resources actively performs concurrent reclamation, reclaiming areas as soon as possible even while mining operations continue. To perform concurrent reclamation, Montana Resources saves and stockpiles soil as it becomes available and recontours completed rock disposal sites to prescribed slopes in a layer thickness determined by the slope profile. It then uses the soil to create grassy rolling hills that are often inhabited by deer and other wildlife. Montana Resources also maintains an active noxious weed control program on mine property.

How is the Berkeley Pit Water Treated?

Montana Resources and Atlantic Richfield Company treat over 3 million gallons of Berkeley Pit water daily, using a complex process to make it clean enough to return to Montana streams. Learn more in the video below.