Montana Resources is part of a modern generation of mine operators. We strive to innovate processes and utilize more efficient technologies that lessen the impact of mining on the environment.

Water Quality

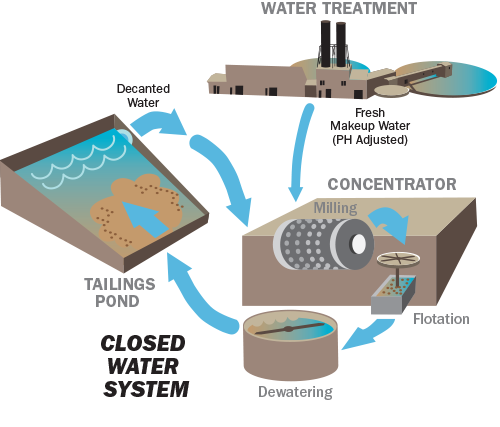

Water is a necessary part of the Montana Resources mine operation. We have in place a closed circuit water system wherein all water used in the mine and concentrator is recycled through the process, with zero discharge to the outside environment. A pulverized rock slurry emerging from the concentrator and thickener tanks is pumped to the Yankee Doodle Tailings Pond where the flour-sized by-product of the milling process settles out before the water is piped back to the mine operation. From this closed circuit not a drop of water leaves the site.

Air Quality

Mining involves rock and machines, but every responsible effort is made to minimize airborne dust finding its way to surrounding areas and neighborhoods.

Water trucks run regularly to wet down our haul roads, minimizing dust caused by mine vehicle traffic.

At all crushing facilities, suction dust collection systems and water sprays are used to capture the fugitive dust.

Montana Resources has upgraded its haul truck fleet with new trucks with 240 ton capacity. The larger trucks move more ore per trip, using less fuel per ton than previous 170 ton trucks, and create less overall dust and diesel emissions.

Non-Ore Rock

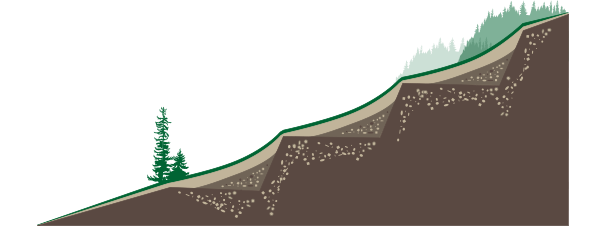

Once non-ore rock is identified, it is hauled to either a non-ore rock repository or used in the tailings dam construction. All of Montana Resources’ non-ore rock repositories are designed to prevent the generation of acid mine drainage. Any non-ore rock determined to contain high-sulfide materials with the capability of creating acidic compounds is encapsulated inside the repository, capped, contoured and revegetated.

Once non-ore rock is identified, it is hauled to either a non-ore rock repository or used in the tailings dam construction. All of Montana Resources’ non-ore rock repositories are designed to prevent the generation of acid mine drainage. Any non-ore rock determined to contain high-sulfide materials with the capability of creating acidic compounds is encapsulated inside the repository, capped, contoured and revegetated.

Non-ore rock is the first layer, followed by pH-neutral alluvium. (For example the reclamation plan specifies slopes less than 5% to receive 28 inches of pH-neutral alluvium with the top 6 inches of alluvium amended to contain 1.5% organic material by weight.) The recontoured area is then seeded with a site-specific recipe of native grasses approved by the Montana Department of Environmental Quality, including bluebunch and crested wheatgrass, blue flax, hard fescue and Russian wild rye.

Reclamation

Commonly, an open pit mine is active for the entire life of the pit, only reclaimed when it becomes dormant. Montana Resources practices concurrent reclamation, reclaiming as soon as possible while mining operations continue. Soil is saved and stockpiled whenever it is available. Completed non-ore rock dumps undergo surface shaping and are recontoured to prescribed slopes in a layer thickness determined by the slope profile. The result creates grassy rolling hills inhabited by deer and other wildlife. Montana Resources also maintains an active noxious weed control program on mine property.